Blog by KIMKOO Mattress Machinery | Digital Diary

" To Present local Business identity in front of global market"

" To Present local Business identity in front of global market"

Digital Diary Submit Post

Digital Diary Submit Post

A clear, professional guide to the Bonnell spring mattress - its core structure, manufacturing steps such as bonnell spring coiling and bonnell spring assembly, and how modern machinery improves quality and efficiency for mattress factories. What Is a Bonnell Spring Mattress? The Bonnell spring mattress is a long-established mattress design favored for its firm support, durability, and cost-effec...

Read More

A clear, professional guide to the Bonnell spring mattress - its core structure, manufacturing steps such as bonnell spring coiling and bonnell spring assembly, and how modern machinery improves quality and efficiency for mattress factories. What Is a Bonnell Spring Mattress? The Bonnell spring mattress is a long-established mattress design favored for its firm support, durability, and cost-effec...

Read More

A clear, professional guide to the Bonnell spring mattress - its core structure, manufacturing steps such as bonnell spring coiling and bonnell spring assembly, and how modern machinery improves quality and efficiency for mattress factories.

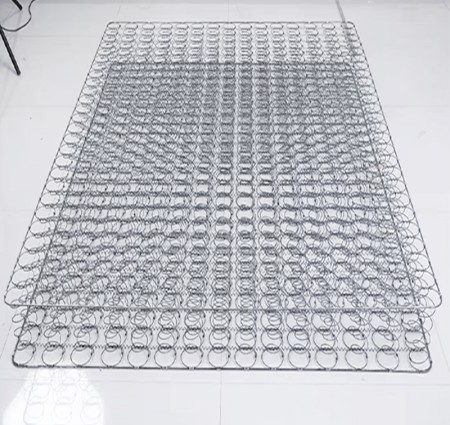

The Bonnell spring mattress is a long-established mattress design favored for its firm support, durability, and cost-effectiveness. Its core is the bonnell spring unit - an interconnected array of hourglass-shaped steel coils held together by helical wiring. This simple but robust construction provides balanced weight distribution, good ventilation, and a reliable lifespan when manufactured correctly.

The bonnell spring unit determines the mattress's support profile. Key attributes - coil shape, wire gauge, coil count, and the accuracy of connections between springs - directly influence firmness, motion transfer, and longevity. Consistency across coils is essential: uneven coils or loose connections will cause sagging and reduce overall comfort.

Two critical manufacturing steps create a high-quality Bonnell core:

Both steps benefit from specialized equipment that increases consistency, speed, and worker safety.

Upgrading production with dedicated machines transforms output quality and operating cost. Professional producers typically use dedicated spring equipment such as a bonnell spring machine, a focused bonnell spring coiling machine, and an efficient bonnell spring assembly machine. These machines deliver:

Although pocket-spring and foam hybrids have grown in popularity, Bonnell mattresses still serve many markets because they are:

For mattress manufacturers seeking to improve Bonnell spring production - from the coil to the finished unit - investing in purpose-built machines yields measurable benefits. Reliable suppliers provide both single machines and integrated production lines to match factory scale and product requirements.

KIMKOO Mattress Machinery is a professional manufacturer and supplier of mattress equipment. We specialize in a wide range of mattress machine solutions including Bonnell spring machines, pocket spring machines, tape edge machines, foam cutting systems, and mattress packaging equipment. Our machines are designed to help factories increase output, improve product consistency, and reduce labor costs.

Want to learn more or get a quote for production equipment such as bonnell spring machine, bonnell spring coiling machine, or bonnell spring assembly machine? Visit our website or contact our sales team for tailored solutions.

Published: September 27, 2025

If you need a shorter media-ready version or a localized edition (Chinese), I can generate that HTML for you as well.

Read Full Blog... A hands-on look at designing, building and scaling Bonnell spring mattress production with an emphasis on process, quality control and the right equipment. Why this matters: For many mattress producers, the Bonnell spring mattress offers the best trade-off between cost, durability and simplicity. With the right process and dependable equipment, factories can increase yield, reduce rework, and deli...

Read More

A hands-on look at designing, building and scaling Bonnell spring mattress production with an emphasis on process, quality control and the right equipment. Why this matters: For many mattress producers, the Bonnell spring mattress offers the best trade-off between cost, durability and simplicity. With the right process and dependable equipment, factories can increase yield, reduce rework, and deli...

Read More

A hands-on look at designing, building and scaling Bonnell spring mattress production with an emphasis on process, quality control and the right equipment.

Why this matters: For many mattress producers, the Bonnell spring mattress offers the best trade-off between cost, durability and simplicity. With the right process and dependable equipment, factories can increase yield, reduce rework, and deliver a consistent product that customers trust.

Before the first coil is formed, lock down your specifications: coil gauge, spring height, turns per spring, spring count per unit and edge support requirements. These design choices determine material use, cycle time and assembly complexity. Standardizing across a few SKUs (e.g., firm, medium, plush) reduces changeover time and simplifies inventory management.

A linear production flow - wire preparation → coiling → tempering → assembly → edging → padding → sewing & inspection - minimizes handling and defects. Add simple traceability (wire batch numbers, coiling run IDs) so you can quickly locate causes when a warranty issue appears.

Consistent coils are the foundation of a stable mattress. A modern bonnell spring coiling machine produces hourglass-shaped springs with repeatable dimensions and pitch. On the floor, apply these practices:

Tempering stabilizes steel microstructure and determines fatigue life. Small temperature or time deviations can change feel and endurance. Implement simple inline checks - hardness, spring height, visual inspection - at set intervals (for example, one sample per 500 springs) to protect long-term performance without halting production.

Converting coils into a stable support unit is a precision task. Using a dedicated bonnell spring assembly machine ensures consistent spacing, secure helical ties and reliable border wire attachment. Practical tips:

Non-woven insulation, foam pad layers and quilting turn a spring unit into a comfortable surface. Use insulation to reduce noise and improve hand feel. Ensure downstream sewing and edge-taping equipment handle your max mattress thickness so finishing is smooth and consistent.

Durability testing (compression cycles, edge load tests) and compliance for target markets prevent returns and legal headaches. If e-commerce is part of your channel strategy, plan for compression and roll-packing - it reduces shipping cost and opens new markets.

Downtime is the hidden cost. Implement a simple maintenance plan for coilers and assembly equipment: daily checks, weekly lubrication, monthly calibration. Keep a small inventory of common wear parts and establish a rapid service channel to minimize lost production.

When choosing suppliers and lines, evaluate beyond initial price:

Optimizing a Bonnell line requires both process discipline and dependable equipment. KIMKOO Mattress Machinery supplies integrated solutions across the Bonnell workflow - from coiling to assembly and final packing. Choosing the right bonnell spring machine, the correct bonnell spring coiling machine and a reliable bonnell spring assembly machine helps manufacturers reduce scrap, raise throughput and deliver consistent products to market.

If your goal is predictable output, lower warranty exposure and faster time-to-market, investing in both process & proven machinery is the fastest path.

Want a concise checklist for auditing your Bonnell production line? We can convert this guide into a printable checklist or a short training slide deck for your floor teams - just ask.

Read Full Blog...