Blog by ZIMLIN Mattress Machinery | Digital Diary

" To Present local Business identity in front of global market"

" To Present local Business identity in front of global market"

Digital Diary Submit Post

Digital Diary Submit Post

The mattress manufacturing industry has seen significant advancements in automation, and one of the most crucial innovations is the automatic mattress tape edge machine. This machine plays a vital role in ensuring mattresses are finished with precision, consistency, and speed, making it an indispensable tool for manufacturers aiming to enhance productivity and product quality. What is an Automatic...

Read More

The mattress manufacturing industry has seen significant advancements in automation, and one of the most crucial innovations is the automatic mattress tape edge machine. This machine plays a vital role in ensuring mattresses are finished with precision, consistency, and speed, making it an indispensable tool for manufacturers aiming to enhance productivity and product quality. What is an Automatic...

Read More

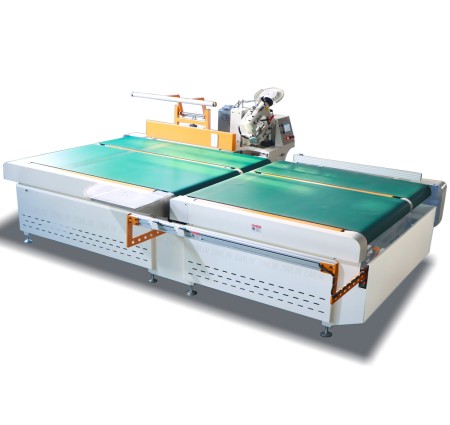

The mattress manufacturing industry has seen significant advancements in automation, and one of the most crucial innovations is the automatic mattress tape edge machine. This machine plays a vital role in ensuring mattresses are finished with precision, consistency, and speed, making it an indispensable tool for manufacturers aiming to enhance productivity and product quality.

An automatic mattress tape edge machine is a specialized piece of equipment designed to sew the edges of mattresses seamlessly. It automates the traditionally labor-intensive process, ensuring uniform stitching, reduced manual labor, and improved efficiency. These machines are equipped with advanced features such as automatic speed control, height adjustment, and precision sewing technology, making them a preferred choice for modern mattress production lines.

Increased Efficiency: Automation reduces the time required for sewing mattress edges, allowing manufacturers to increase their production capacity significantly.

Consistent Quality: Unlike manual stitching, automated machines ensure uniform seams, improving the overall quality and durability of mattresses.

Reduced Labor Costs: By automating the sewing process, manufacturers can minimize dependency on skilled labor, leading to cost savings.

Versatility: Many tape edge machines are designed to handle various mattress sizes and thicknesses, offering flexibility in production.

User-Friendly Operation: Modern automatic mattress sewing machines come with intuitive controls, making them easy to operate even for non-experts.

Tape edge machines are essential in ensuring that mattress edges are securely stitched, preventing material fraying and maintaining structural integrity. These machines are available in both semi-automatic and fully automatic models, allowing manufacturers to choose based on their production needs.

A mattress sewing machine is a critical component of mattress production, ensuring that all layers of the mattress are held together firmly. With advancements in technology, fully automatic models have become the standard for large-scale mattress manufacturers, reducing error rates and enhancing operational efficiency.

ZIMLIN Mattress Machinery is one of the largest mattress machine manufacturers in China, specializing in the production of high-quality mattress machinery. With years of experience in the industry, ZIMLIN offers a wide range of innovative and reliable solutions, including automatic mattress tape edge machines, to help mattress manufacturers improve their production efficiency and product quality.

For more information about our tape edge machines and other mattress manufacturing solutions, visit our website at ZIMLIN Mattress Machinery.

Read Full Blog... In the modern era of mattress distribution, innovative packaging techniques are crucial for optimizing logistics, minimizing costs, and enhancing product presentation. ZIMLIN Mattress Machinery offers state-of-the-art mattress compression machine tailored to meet these demands. This guide explores how to compress and roll pack foam and pocket coil mattresses using advanced machinery. Compress...

Read More

In the modern era of mattress distribution, innovative packaging techniques are crucial for optimizing logistics, minimizing costs, and enhancing product presentation. ZIMLIN Mattress Machinery offers state-of-the-art mattress compression machine tailored to meet these demands. This guide explores how to compress and roll pack foam and pocket coil mattresses using advanced machinery. Compress...

Read More

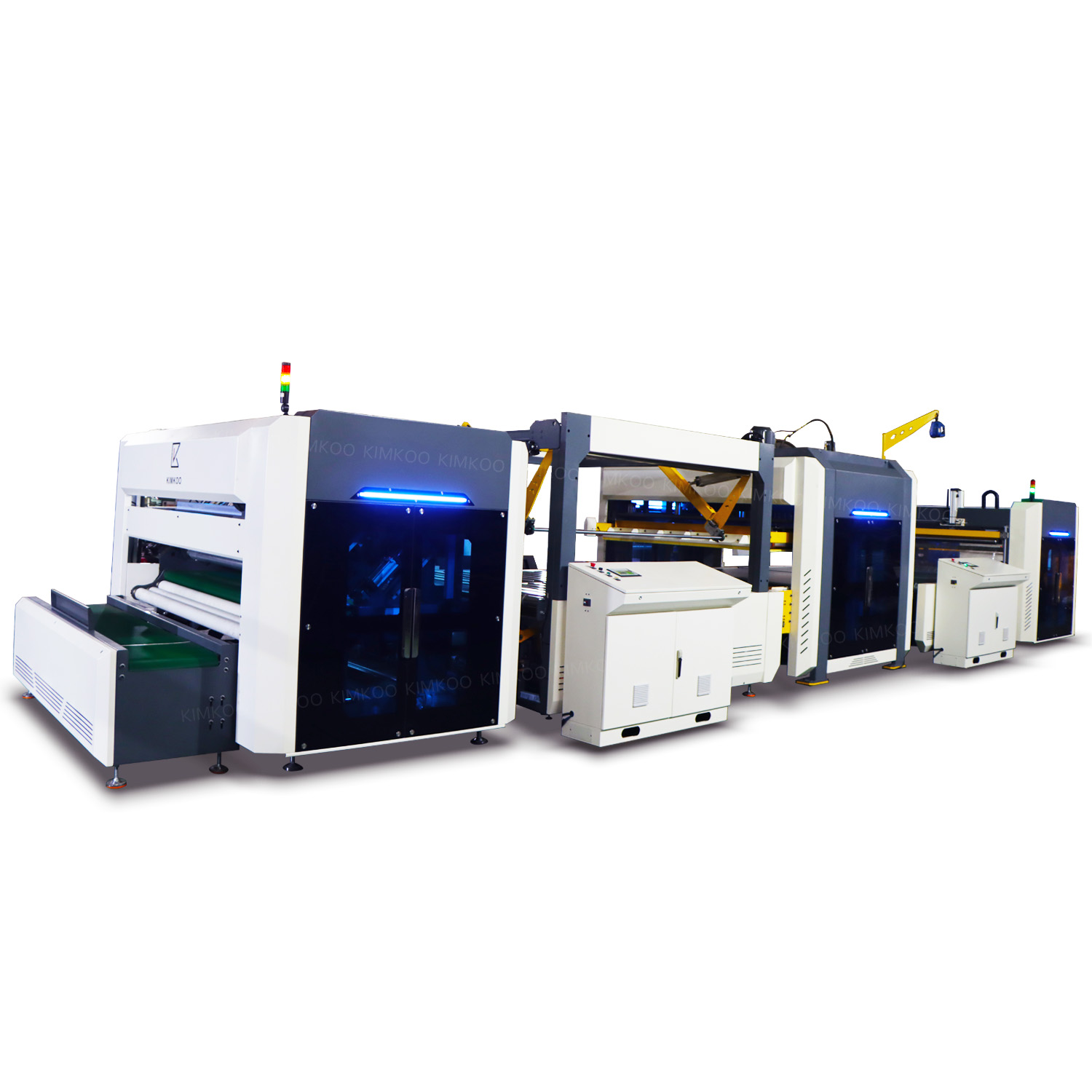

In the modern era of mattress distribution, innovative packaging techniques are crucial for optimizing logistics, minimizing costs, and enhancing product presentation. ZIMLIN Mattress Machinery offers state-of-the-art mattress compression machine tailored to meet these demands. This guide explores how to compress and roll pack foam and pocket coil mattresses using advanced machinery.

Foam mattresses are known for their flexibility and lightweight properties, making them ideal candidates for compression packaging. Here's how the process unfolds:

Precision Compression: Using ZIMLIN's advanced compression technology, the foam mattress is flattened to a fraction of its original size, achieving a compression ratio of up to 9:1. This process ensures the mattress retains its shape and quality after decompression.

Heat Sealing: A durable PE or PVC film bag encases the compressed mattress, and a heat-sealing bar securely seals the packaging. This robust seal ensures the mattress remains compact and protected during transit.

Roll Packing: The machine's intelligent system automatically adjusts to the dimensions of the mattress, rolling it into a convenient cylindrical shape. This compact form is ideal for shipping and storage, aligning with the growing demand for 'mattress in a box' solutions.

Pocket coil mattresses, with their intricate spring systems, require specialized handling during compression. ZIMLIN's machines are designed to address these challenges with ease:

Gentle Compression: Controlled pressure is applied to flatten the mattress while preserving the structural integrity of its coils. This ensures the mattress delivers the same level of comfort after unpacking.

Secure Packaging: The heat-sealing function ensures the packaging material fits snugly around the compressed mattress, preventing damage during transport.

Custom Roll Packing: With its adaptive design, the roll-packing system accommodates the unique dimensions of pocket coil mattresses, creating a compact package ready for shipping.

ZIMLIN's mattress compression packing machine is engineered to optimize the packaging process, offering several benefits:

Increased Efficiency: Compress and roll pack mattresses in just 35 seconds, maximizing productivity.

Space Optimization: Compact packaging reduces storage requirements, allowing more products to fit in warehouses and shipping containers.

Cost Reduction: Lower packaging volume translates to significant savings on transportation and labor expenses.

Enhanced Market Appeal: Cylindrical roll-packed mattresses are ideal for e-commerce, retail, and direct-to-consumer delivery models.

As a top-tier manufacturer of mattress machinery in China, ZIMLIN is committed to advancing the industry with reliable and efficient solutions. Whether you're looking to learn how to compress a foam mattress or understand the nuances of handling pocket coil models, our machines offer the perfect combination of precision and performance.

Transform your packaging process with ZIMLIN's cutting-edge mattress compression packing machines. Contact us today to explore how our solutions can meet your business's unique needs.

Read Full Blog... Efficient packaging is at the heart of modern mattress manufacturing, ensuring streamlined logistics and reduced costs. Zimlin Mattress Machinery, a leader in packaging innovation, offers an advanced mattress roll packing machine that simplifies the packing process while maintaining the quality of mattresses. Spearheaded by CEO Vito Chan, Zimlin provides reliable solutions that are transformi...

Read More

Efficient packaging is at the heart of modern mattress manufacturing, ensuring streamlined logistics and reduced costs. Zimlin Mattress Machinery, a leader in packaging innovation, offers an advanced mattress roll packing machine that simplifies the packing process while maintaining the quality of mattresses. Spearheaded by CEO Vito Chan, Zimlin provides reliable solutions that are transformi...

Read More

Efficient packaging is at the heart of modern mattress manufacturing, ensuring streamlined logistics and reduced costs. Zimlin Mattress Machinery, a leader in packaging innovation, offers an advanced mattress roll packing machine that simplifies the packing process while maintaining the quality of mattresses. Spearheaded by CEO Vito Chan, Zimlin provides reliable solutions that are transforming the way mattresses are packaged and transported.

Why Roll-Packing Is the Best Choice

Mattress roll-packing has become the industry standard for efficient storage and transport. By compressing and rolling mattresses into compact cylinders, manufacturers can save significant storage space and lower shipping costs. The roll-packing method also improves handling, making it easier for warehouses, retailers, and consumers to manage and store products.

Zimlin's mattress packing machine takes this concept further by automating the process, ensuring a faster, safer, and more consistent method of preparing mattresses for shipping.

Effortless Speed and Precision

One of the key advantages of Zimlim's automatic mattress packing machine is its exceptional speed. The machine can compress and roll mattresses in a matter of seconds, making it an essential tool for factories that need to process large volumes quickly. Its automated features allow for continuous operation with minimal intervention, boosting productivity and reducing labor costs.

The precision of the machine ensures that each mattress is packed to the exact specifications required, protecting the mattress from damage during transit while keeping its structure intact. Whether handling foam, hybrid, or spring mattresses, Zimlin's machine delivers reliable results with every use.

Versatility to Match Diverse Needs

Zimlin's mattress roll packing machine is designed with versatility in mind. It can accommodate mattresses of various sizes, from compact twin mattresses to oversized king models. The adjustable compression settings ensure compatibility with different mattress thicknesses and materials, providing a tailored packing solution for every product.

This flexibility makes Zimlin's machine ideal for manufacturers with diverse product lines, allowing them to meet the unique demands of their customers without compromising efficiency.

Durability and Sustainability

Built with high-quality materials and advanced engineering, Zimlin's mattress roll packing machine offers unmatched durability. Its robust design ensures consistent performance, even under heavy usage, reducing maintenance costs and machine downtime.

In addition to its reliability, the machine is energy-efficient, helping manufacturers minimize their environmental impact. By reducing the volume of packaging materials and optimizing transportation loads, Zimlin supports eco-friendly practices that benefit both businesses and the planet.

Perfect for Mattress Factories of All Sizes

Whether you're operating a high-capacity production line or a smaller-scale facility, Zimlin's roll packing machine is the perfect solution. Its user-friendly design and intuitive controls make it easy to integrate into existing workflows, while its high-speed performance ensures that production deadlines are consistently met.

The machine's compact design also makes it a space-saving addition to any factory floor, ideal for manufacturers looking to maximize operational efficiency.

Zimlin: A Name You Can Trust

As a trusted name in the mattress machinery industry, Zimlin Mattress Machinery has a proven track record of delivering innovative, high-quality solutions. With a commitment to customer satisfaction and technological advancement, Zimlin has become a preferred partner for mattress manufacturers around the globe. CEO Vito Chan's vision for the company continues to drive its success, ensuring that Zimlin remains at the forefront of industry innovation.

Conclusion

Zimlin's mattress roll packing machine is revolutionizing the packaging process, offering manufacturers a fast, versatile, and cost-effective way to roll-pack mattresses for shipping. Its automated features, durable design, and energy-efficient operation make it the ideal choice for businesses aiming to optimize their production lines.

Whether you're scaling up production or enhancing efficiency, Zimlin's roll packing machine provides the tools you need to stay ahead in the competitive mattress industry.

Read Full Blog... Zimlin Mattress Machinery, a leading innovator in industrial machinery for the bedding sector, has announced the launch of its latest breakthrough product: the all-new automatic tape edge machine. Designed to elevate the standard of mattress manufacturing, this state-of-the-art equipment offers unmatched efficiency, precision, and scalability to meet the diverse needs of modern bedding producers....

Read More

Zimlin Mattress Machinery, a leading innovator in industrial machinery for the bedding sector, has announced the launch of its latest breakthrough product: the all-new automatic tape edge machine. Designed to elevate the standard of mattress manufacturing, this state-of-the-art equipment offers unmatched efficiency, precision, and scalability to meet the diverse needs of modern bedding producers....

Read More

Zimlin Mattress Machinery, a leading innovator in industrial machinery for the bedding sector, has announced the launch of its latest breakthrough product: the all-new automatic tape edge machine. Designed to elevate the standard of mattress manufacturing, this state-of-the-art equipment offers unmatched efficiency, precision, and scalability to meet the diverse needs of modern bedding producers.

The new automatic tape edge machine by Zimlin introduces a transformative approach to the critical final step of mattress production. Known for its durability and versatility, the machine is equipped with cutting-edge technology that streamlines the process of securing mattress edges, significantly reducing both labor costs and production time while enhancing the overall quality of the final product.

Enhanced Productivity and Precision

One of the key highlights of the automatic tape edge machine is its ability to handle high-volume production with remarkable consistency. The machine's precision control system ensures that each mattress is finished with uniform tape application along the edges, delivering a professional and polished result every time. Manufacturers will find the machine's high-speed capabilities, combined with easy integration into existing production lines, to be an invaluable asset in boosting throughput.

The machine also offers an innovative feature: smart adjustments that can automatically adapt to different mattress types and sizes, from traditional innerspring to memory foam and hybrid mattresses. These advancements provide a seamless experience for manufacturers and help minimize downtime between production runs.

Key Features of the New Automatic Tape Edge Machine:

A Step Toward Future-Proof Mattress Production

"We've designed this new automatic tape edge machine to meet the growing demands of mattress manufacturers who are seeking to stay competitive in an increasingly fast-paced industry," said Vito Chan, CEO of Zimlin Mattress Machinery. "This machine isn't just about automation – it's about elevating the entire production process, ensuring superior product quality, and reducing costs."

The introduction of Zimlin's new automatic tape edge machine is set to redefine how mattress manufacturers approach efficiency, consistency, and innovation in their production lines. With the ability to integrate seamlessly into both large and small operations, this machine represents a leap forward in the automation of mattress production.

ZIMLIN also manufactures a wide range of tape edge machines, including Semi-auto tape edge machines. These machines come with optional sewing head choices such as Seiko, Typical, and Singer 300U for enhanced versatility and performance.

About Zimlin Mattress Machinery

Zimlin Mattress Machinery has been at the forefront of providing advanced solutions for the global mattress manufacturing industry. With a strong commitment to research and development, the company has consistently introduced groundbreaking technology that enhances both the quality and speed of mattress production. Zimlin's equipment is trusted by leading manufacturers around the world to deliver durable, high-performance solutions.

For more information on Zimlin's new automatic tape edge machine or to schedule a demonstration, visit www.zimlin.com or contact the sales team directly.

Read Full Blog... Zimlin, a pioneer in mattress and foam machinery, has introduced a new line of high-performance mattress compression machines and foam block compression machines, setting a new standard in the packaging industry. The innovative machines are designed to improve efficiency, reduce costs, and ensure the safe transport of foam mattresses and blocks, revolutionizing packaging processes for manufacturer...

Read More

Zimlin, a pioneer in mattress and foam machinery, has introduced a new line of high-performance mattress compression machines and foam block compression machines, setting a new standard in the packaging industry. The innovative machines are designed to improve efficiency, reduce costs, and ensure the safe transport of foam mattresses and blocks, revolutionizing packaging processes for manufacturer...

Read More

Zimlin, a pioneer in mattress and foam machinery, has introduced a new line of high-performance mattress compression machines and foam block compression machines, setting a new standard in the packaging industry. The innovative machines are designed to improve efficiency, reduce costs, and ensure the safe transport of foam mattresses and blocks, revolutionizing packaging processes for manufacturers around the world.

Optimizing Mattress Packaging Solutions

Zimlin's mattress compression packing machine is a game-changer for manufacturers, enabling them to compress foam mattresses to a fraction of their original size. This reduction in size helps businesses optimize storage space and cut down on shipping costs. The machine's advanced technology allows for precision compression, ensuring that mattresses retain their quality and durability while being compacted.

This compression technology is particularly beneficial for businesses dealing with memory foam or high-density foam products, which require careful handling to avoid damage. Zimlin's mattress compression machine maintains the foam's integrity during the compression process, ensuring products reach customers in perfect condition.

Efficient Foam Block Compression Technology

In addition to mattress solutions, Zimlin has also rolled out an advanced foam block compression machine, specifically designed for foam block producers. This new machine allows manufacturers to compress large foam blocks, reducing their volume significantly while maintaining product quality.

The foam compression machine features customizable settings, making it versatile enough for various types of foam materials. This flexibility allows manufacturers to maximize storage capacity and improve transportation efficiency, addressing the growing demand for cost-effective and sustainable packaging.

Performance, Precision, and Sustainability

The standout feature of Zimlin's new machines is their commitment to sustainability and energy efficiency. By reducing the space required for shipping, these machines help manufacturers cut down on fuel consumption and carbon emissions during transport. The user-friendly interface ensures ease of operation, while the automated monitoring systems guarantee safe and accurate compression cycles.

Zimlin's machines are built to meet the highest safety standards, with built-in sensors to monitor pressure and prevent overloading, providing peace of mind to operators and manufacturers alike.

Global Impact on the Foam Industry

With the launch of these advanced mattress compression packing machines and foam block compression machines, Zimlin is positioning itself as a leader in the global foam and mattress machinery market. As demand for foam products continues to rise worldwide, these innovations promise to streamline operations, reduce waste, and offer manufacturers a cost-effective solution to meet increasing consumer needs.

Zimlin's commitment to technological advancements and sustainability ensures that these machines will play a key role in transforming the future of foam and mattress packaging, offering both economic and environmental benefits.

For more details on Zimlin's mattress and foam compression solutions, visit their website or reach out to their customer service team.

About Zimlin Mattress Machinery

Zimlin is an industry-leading provider of machinery solutions for the mattress and foam sectors. Zimlin is one of the largest mattress machine manufacturers in China, specializing in the production of high-quality mattress machinery. We produce high-performance mattress machines, such as pocket spring machines, pocket spring assembly machines, mattress packing machines, mattress tape edge machines, pillow packing machines, foam cutting machines... etc.Known for its cutting-edge technology and innovative designs, Zimlin is committed to helping manufacturers improve production efficiency, reduce costs, and enhance product quality. From mattress compression packing machines to foam block compression equipment, Zimlin delivers reliable, high-performance solutions for the global market.

Read Full Blog... Guangdong, China – ZIMLIN Mattress Machinery, a renowned leader in mattress machinery manufacturing, is making waves with its innovative foam compression machines, transforming how foam and bedding products are packaged and transported. These machines, also referred to as foam block compression machine or foam compression packing machine, deliver an astounding 90% reduction in packaging...

Read More

Guangdong, China – ZIMLIN Mattress Machinery, a renowned leader in mattress machinery manufacturing, is making waves with its innovative foam compression machines, transforming how foam and bedding products are packaged and transported. These machines, also referred to as foam block compression machine or foam compression packing machine, deliver an astounding 90% reduction in packaging...

Read More

Guangdong, China – ZIMLIN Mattress Machinery, a renowned leader in mattress machinery manufacturing, is making waves with its innovative foam compression machines, transforming how foam and bedding products are packaged and transported.

These machines, also referred to as foam block compression machine or foam compression packing machine, deliver an astounding 90% reduction in packaging volume. This breakthrough technology is designed for foam blocks, foam sofas, spring sofas, and mattresses, providing businesses with a powerful tool to maximize storage efficiency and minimize shipping costs.

The ZIMLIN foam compression machine combine cutting-edge engineering with user-friendly functionality. By compressing bulky items into compact, roll-packaged forms, these machines simplify logistics while ensuring product integrity during transportation. Their applications span a variety of industries, catering to manufacturers of foam products and upholstered furniture.

Manufactured in Guangdong, China, ZIMLIN's machines underscore the company's reputation for excellence. As one of the largest mattress machinery manufacturers in the country, ZIMLIN has set a high standard for quality and innovation, delivering robust and efficient solutions tailored to the evolving demands of the global market. ZIMLIN Product Range Includes: pocket spring machine, pocket spring assembly machines, mattress roll packing machine, mattress tape edge machine, pillow packing machine, foam cutting machine... etc.

With ZIMLIN's foam compression technology, manufacturers can significantly cut storage and freight costs, making their operations more sustainable and competitive. This cutting-edge approach aligns with industry trends toward optimized supply chains and reduced environmental impact.

ZIMLIN Mattress Machinery continues to lead the charge in revolutionizing the furniture and bedding industry, providing practical solutions for businesses worldwide. For more details, visit ZIMLIN Mattress Machinery.

Read Full Blog... The mattress industry has witnessed a significant shift in how products are packaged and transported, thanks to the introduction of Zimlin's innovative automatic mattress packing machine. This cutting-edge technology is designed to automate the entire packaging process, including compression, bagging, sealing, folding, and roll-packing, making mattress packaging faster and more efficient than...

Read More

The mattress industry has witnessed a significant shift in how products are packaged and transported, thanks to the introduction of Zimlin's innovative automatic mattress packing machine. This cutting-edge technology is designed to automate the entire packaging process, including compression, bagging, sealing, folding, and roll-packing, making mattress packaging faster and more efficient than...

Read More

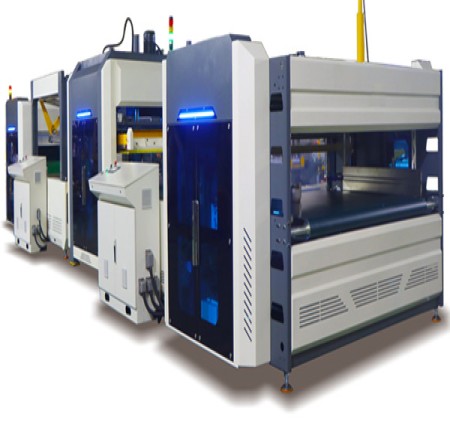

The mattress industry has witnessed a significant shift in how products are packaged and transported, thanks to the introduction of Zimlin's innovative automatic mattress packing machine. This cutting-edge technology is designed to automate the entire packaging process, including compression, bagging, sealing, folding, and roll-packing, making mattress packaging faster and more efficient than ever before.

The mattress roll packing machine from Zimlin is capable of completing the entire process in just 45 seconds, offering an unmatched combination of speed and precision. This rapid processing time allows mattress manufacturers to boost production output while maintaining a consistent, high-quality packaging standard.

Key Advantages of the Mattress Roll Pack Machine

One of the standout benefits of the mattress roll pack machine is the substantial reduction in volume after the mattress is compressed and rolled. This not only makes it easier to handle and store the product but also results in considerable savings in shipping costs. A more compact product means more efficient use of space during transportation, leading to lower freight charges.

Beyond shipping, the machine also addresses space constraints in warehouses. By minimizing the volume of each mattress, it maximizes storage capacity, reducing the need for extensive storage space and ultimately cutting down on warehouse expenses.

Streamlining Labor Costs and Improving Workflow Efficiency

The automatic mattress packing machine reduces the need for manual labor, offering significant savings on staffing costs. Automation allows manufacturers to allocate resources more efficiently, reducing the potential for human error and improving overall workflow.

Furthermore, the efficiency of the system improves production speed and consistency, enabling manufacturers to meet higher demand without compromising quality. This not only makes businesses more profitable but also more competitive in the marketplace.

Zimlin Mattress Machinery: Pioneering Innovation in Mattress Manufacturing

Zimlin Mattress Machinery is a recognized leader in the mattress machinry equipment industry, offering a comprehensive range of machines that enhance production efficiency. In addition to the mattress roll packing machine, Zimlin also produces mattress compression machine, foam cutting machine, pocket spring coiling machine, and tape edge machine-each designed to optimize the production process.

With a focus on quality and innovation, Zimlin has established itself as a trusted partner for manufacturers worldwide, providing reliable and effective solutions that improve operational efficiency.

Conclusion

Zimlin's automatic mattress packing machine represents a major step forward for the mattress industry. Its ability to significantly reduce packaging time, lower shipping costs, and streamline labor processes makes it a valuable investment for manufacturers looking to optimize production and distribution. With Zimlin's technology, mattress companies can improve both their operational efficiency and their bottom line, positioning themselves for success in an increasingly competitive global market.

Read Full Blog... When it comes to packaging foam blocks, whether for shipping or storage, the process requires careful consideration to ensure the foam remains intact, compressed, and easy to transport. Foam blocks are often used in the manufacturing of mattresses, cushions, and various types of protective packaging. Understanding the proper techniques and machinery involved can save time, reduce costs, and improv...

Read More

When it comes to packaging foam blocks, whether for shipping or storage, the process requires careful consideration to ensure the foam remains intact, compressed, and easy to transport. Foam blocks are often used in the manufacturing of mattresses, cushions, and various types of protective packaging. Understanding the proper techniques and machinery involved can save time, reduce costs, and improv...

Read More

When it comes to packaging foam blocks, whether for shipping or storage, the process requires careful consideration to ensure the foam remains intact, compressed, and easy to transport. Foam blocks are often used in the manufacturing of mattresses, cushions, and various types of protective packaging. Understanding the proper techniques and machinery involved can save time, reduce costs, and improve overall product quality. Here's a step-by-step guide to packaging foam blocks effectively.

The first step in packaging foam blocks is understanding the importance of compression. Foam materials, particularly in bulk, can take up significant space. Compressing foam blocks reduces their size, making them easier to package, store, and transport. This is especially critical for industries like mattress manufacturing, where foam must be tightly packed to fit in shipping containers or retail packaging.

A foam block compression machine is commonly used to compress foam blocks. These machines apply controlled pressure to reduce the volume of foam, allowing for efficient packaging. Whether you are working with memory foam, polyurethane foam, or other types, a compression machine is an essential tool in modern packaging systems.

Selecting the right foam compression machine is vital to ensure the foam is compressed evenly without damaging its integrity. Several manufacturers, such as Zimlin Mattress Machinery, offer advanced designs in foam block compression machines. These machines are designed to handle different foam densities and compress them to a manageable size for easier packaging and transportation.

The new design foam block compression machines from Zimlin, for example, use high-quality hydraulic systems that offer precise control over the amount of pressure applied. This ensures that foam blocks are not crushed excessively, which can negatively impact the foam's quality.

Before using a compression machine, make sure the foam is clean and dry. Any dirt or moisture in the foam can compromise the final product. If you're working with larger foam blocks, it's a good idea to cut them down into smaller sections for easier handling.

Once the foam is prepped, place it into the compression machine. The foam block pressing machine will apply pressure to the foam, reducing its volume significantly. Most modern machines have automated settings that allow you to control the level of compression and the time it takes.

The foam compression machine will usually have a platform where foam blocks are placed, followed by rollers or hydraulic presses that apply even pressure. The result is a compressed foam block that is easier to handle and ready for packaging.

Once the foam is compressed, it's time to package it. There are various methods to do this, depending on the type of foam and the specific requirements of your shipment or storage needs. Common packaging methods include:

Finally, after packaging, the compressed foam blocks should be stored in a cool, dry area until they're ready for shipping. For transportation, make sure to handle the foam with care to avoid unintentional expansion, especially when using vacuum-sealed packaging.

Packaging foam blocks requires an efficient combination of compression, the right machinery, and proper packaging materials. Using a foam block compression machine, like those designed by Zimlin Mattress Machinery, ensures that your foam blocks are compressed efficiently without compromising quality. With the correct tools and techniques, packaging foam blocks becomes a streamlined process that helps improve efficiency and reduce shipping costs. Whether you're packing foam for mattresses, cushions, or protective packaging, mastering the art of compression and packaging is crucial for maintaining product integrity and optimizing logistics.

ZIMLIN Mattress Machinery is one of the largest mattress machines manufacturer in China, specializing in the production of high-quality mattress machinery.

Read Full Blog... Foam block compression is a crucial process for industries aiming to optimize space, cut shipping costs, and maintain product quality. Using a top-tier foam press machine is essential for achieving efficient and reliable results. ZIMLIN Mattress Machinery, a prominent leader in the mattress machines sector, provides cutting-edge solutions designed to meet these needs. Essential Functions of a Foam...

Read More

Foam block compression is a crucial process for industries aiming to optimize space, cut shipping costs, and maintain product quality. Using a top-tier foam press machine is essential for achieving efficient and reliable results. ZIMLIN Mattress Machinery, a prominent leader in the mattress machines sector, provides cutting-edge solutions designed to meet these needs. Essential Functions of a Foam...

Read More

Foam block compression is a crucial process for industries aiming to optimize space, cut shipping costs, and maintain product quality. Using a top-tier foam press machine is essential for achieving efficient and reliable results. ZIMLIN Mattress Machinery, a prominent leader in the mattress machines sector, provides cutting-edge solutions designed to meet these needs.

A foam block press machine offers several critical functions that enhance packaging efficiency:

Compression: The machine compresses foam blocks efficiently, achieving a significant 23:1 volume reduction ratio. This compacting ability allows for easier storage and cost-effective shipping while preserving the foam's original structure.

Heat Sealing: Advanced heat-sealing technology ensures a tight and secure seal, preventing air leaks and maintaining the foam's integrity throughout transit.

ZIMLIN's foam press machines are equipped with a sophisticated PLC control system that promotes high safety standards. The system features an emergency stop switch, providing an added layer of safety for operators. The entire compression and packaging cycle is completed in just 35 seconds, which helps to lower labor costs and boost overall operational efficiency.

The machine's low packing costs make it a smart investment for businesses looking to enhance their packaging processes while keeping expenses in check.

The machine's versatility allows it to handle a variety of foam block sizes, compressing them into flat-pack shapes without compromising the foam's quality. This adaptability makes it ideal for businesses requiring flexible solutions for different foam block sizes and shapes.

With a rich history spanning over 16 years, ZIMLIN Mattress Machinery has established itself as a leading force in the production of mattress and foam compression equipment. Their commitment to production, manufacturing, and research & development ensures that their machines meet the highest standards of quality and efficiency.

ZIMLIN's foam block press machines are designed to provide reliable, efficient, and cost-effective solutions for a range of industries. By leveraging advanced technology and a deep understanding of industry needs, ZIMLIN continues to offer innovative products that help businesses optimize their operations.

For those seeking to improve their foam compression processes, ZIMLIN Mattress Machinery offers unparalleled technology and expertise, making them the ideal partner for achieving packaging excellence.

Read Full Blog... In the fast-evolving mattress industry, efficiency and cost-effectiveness are key drivers of success. Enter the automatic mattress packing machine, an innovation that streamlines the entire packaging process. Designed to handle everything from auto bagging to compression, heat sealing, conveying, folding, and rolling, this machine takes just 45 seconds to complete the task, significantly enhancing...

Read More

In the fast-evolving mattress industry, efficiency and cost-effectiveness are key drivers of success. Enter the automatic mattress packing machine, an innovation that streamlines the entire packaging process. Designed to handle everything from auto bagging to compression, heat sealing, conveying, folding, and rolling, this machine takes just 45 seconds to complete the task, significantly enhancing...

Read More

In the fast-evolving mattress industry, efficiency and cost-effectiveness are key drivers of success. Enter the automatic mattress packing machine, an innovation that streamlines the entire packaging process. Designed to handle everything from auto bagging to compression, heat sealing, conveying, folding, and rolling, this machine takes just 45 seconds to complete the task, significantly enhancing both the visual appeal of mattress packaging and operational efficiency.

Why Automatic Mattress Packing Machines Matter

For manufacturers, the advantages of an automatic mattress packing machine are undeniable. These machines are built to reduce manual labor while increasing output. By compressing and rolling the mattress, they significantly minimize storage and shipping volumes. A key benefit is the ability to transform a standard mattress into a compact form that fits into a box, allowing retailers and manufacturers to meet the rising demand for "mattress in a box" solutions. This format is particularly advantageous for e-commerce, where shipping costs are a major consideration.

Post roll-packing, the mattress volume can be reduced by as much as 70%, leading to substantial savings in shipping and storage. The compact size also allows for easier transportation and handling, enabling businesses to deliver more mattresses per shipment, ultimately lowering logistics costs.

Key Functions of the Mattress Packing Machine

The mattress packing machine offers a variety of essential features:

In just 45 seconds, these processes are completed, delivering a compact, neatly packed mattress.

ZIMLIN Mattress Machinery: A Leader in Innovation

As one of the largest mattress machine manufacturers in China, ZIMLIN Mattress Machinery has been a driving force behind this packaging revolution. With over 16 years of industry experience, ZIMLIN excels in integrating production, manufacturing, and research & development to produce cutting-edge machinery that meets global standards. Their mattress packing machines, including mattress compression machine and mattress roll packing machine, are designed to offer superior efficiency, reduce labor costs, and optimize shipping and storage.

ZIMLIN's machines are particularly valued for their ability to deliver high-quality results, helping businesses adapt to the increasing demand for compact, easy-to-ship mattresses.

Conclusion

In today's competitive market, having the right equipment can make all the difference. An automatic mattress packing machine offers businesses a way to reduce costs, improve packaging quality, and meet the growing demand for "mattress in a box" solutions. ZIMLIN Mattress Machinery, with its innovative approach and commitment to quality, stands at the forefront of this revolution, providing machinery that enhances efficiency and drives success.

Whether you're in manufacturing, retail, or e-commerce, investing in a mattress roll pack machine can transform your operations and set your business up for long-term growth.

Read Full Blog...